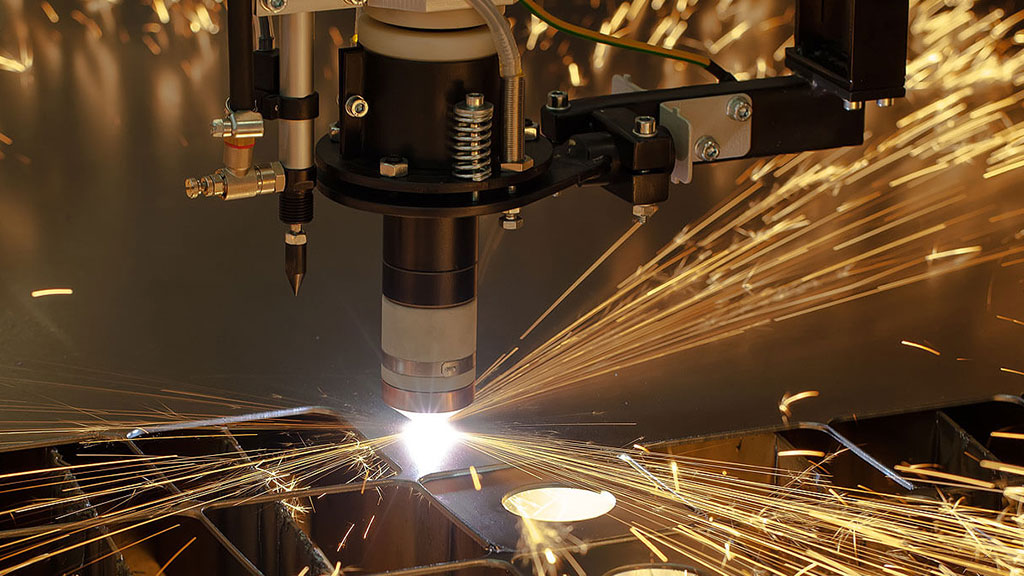

Plasma cutting machine with different working gas can cut all kinds of metal that is difficult to cut with oxygen, especially for non-ferrous metal materials (carbon steel, stainless steel, copper, aluminum, nickel, titanium); the main advantage is that the cutting thickness is not For large metals, the plasma cutting speed is fast, especially when cutting ordinary carbon steel sheets, the speed can reach 5-6 times of the oxygen cutting method, the cutting surface is smooth, the thermal deformation is small, and there is almost no heat affected zone. The advantages of the plasma cutting machine are that the plasma arc energy is more concentrated, the temperature is higher, the cutting speed is faster, and the deformation is small. It can also cut stainless steel, aluminum and other materials. The shortcomings of plasma cutting are arc intensity, noise, dust, and pollution to the environment. For medium thickness, underwater plasma cutting is used, and the cutting thickness is also limited. Similarly, gas flow, arc length, telegram quality, current size, and cutting speed all affect the quality. It is not easy to master if you do not master well. It is hard to use than flame cutting. Plasma cutter gun is not fit, because the cutting speed is high, and it easily creates contradictions due to the above factors, which makes the cutting quality different. Generally speaking, for thin plate cutting, the surface quality of plasma cutting incision is better than that of fire filling cutting, and there is very little slag.