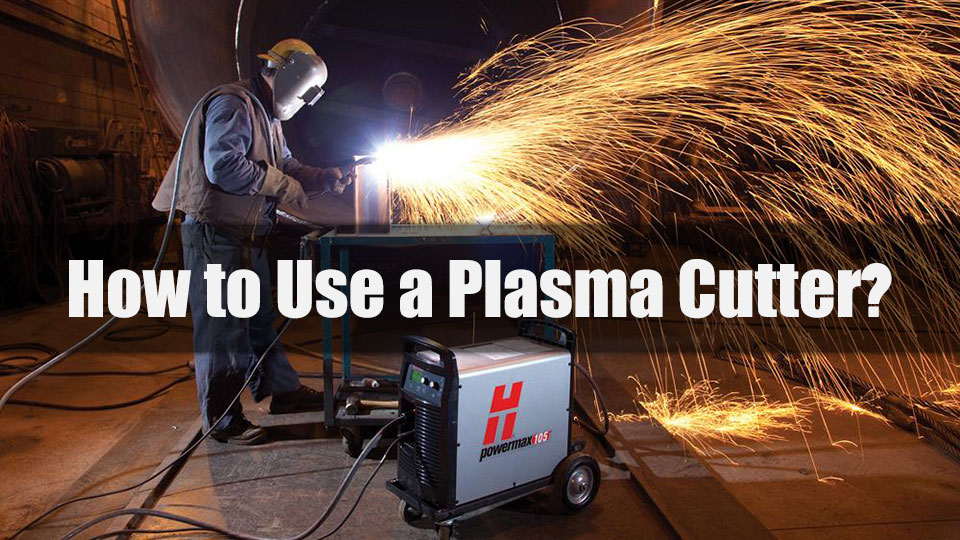

A Guide to Use a Plasma Cutter

Jimmy Posted on Feb 26, 2020

Plasma cutters work by sending an electric arc through a gas that is passing through a constricted opening. The gas can be shop air, nitrogen, argon, oxygen. etc. This elevates the temperature of the gas to the point that it enters a 4th state of matter. We all are familiar with the first three: i.e., solid, liquid, and gas. Scientists call this additional state plasma. As the metal being cut is part of the circuit, the electrical conductivity of the plasma causes the arc to transfer to the work.

The act of using a plasma cutter is often labeled as convenient and comfortable, but we should obtain the proper way to do it. To give you a guide, here are the following steps:

Step 1. Apply Safety Measures

When using a plasma cutter, ensure that you wear safety goggles for ultraviolet radiations and other debris that may come in contact with your eye. Protective clothing and gloves are also essential to protect burns.

Step 2. Appropriate Work Location

Choose a suitable area that is not prone to fire or has access to any type of gasses. Place the sheet of metal on a safe location that gives you access to sudden freedom of movement. A table to hold it stable is necessary.

Step 3. Plug the Unit and Connect an Air Compressor

Keep in mind that the unit should be off before you plug it in. After this, join the plasma cutter to the air compressor for the plasma to remain in high pressure while on the process of metal cutting.

Step 4. Keep the Air Flowing and Attach the Clamp

Keep the flow of air throughout the process, specifically; the lever should be rotated to the inline at a ninety-degree angle. Then, attach the clamp to the metal to keep it stable. The brace should be attached near the spot where you will be cutting.

Step 5. Turning the Machine on and Setting the Current

It depends on your plasma cutter, but usually, you flip the switch behind the machine to turn it on. When it is turned on, keep in mind that the current depends on your work and the duration of the cutting period.

A one-meter cut of metal regarding current is different from some inches long. To start, you can set to 25 for 18-gauge metal.

Step 6. Cut the Metal Depending on Your Desired Size

You can locate the safety on the gun that should be lifted before activating the trigger. The nozzle of the gun should be near the metal sheet and trace the template using a guide of your choice that surrounds the nozzle.

Step 7. Turn Off the Plasma Cutter

Once finished, turn off the machine. After doing so, disconnect the clamp from your metal. The air should be turned off by rotating the lever that is currently at the inline to the airline at a ninety-degree angle. Moreover, make sure that all of the hoses are wind up, including the airline, ground line, and plasma gun.